Raewood is a Voller brand, which also serves as a mark of quality.

The brand defines the company's identity since 2023. The mark embodies quality, art, dedication, and professionalism. Based on the brand name, it is easy to identify our origin and field of activity.

Raewood designs and manufactures a wide range of solid wood and wood-based material interior and acoustic solutions. We specialize in providing custom solutions, covering the entire process - from design and production to installation.

Our products

Our products are inspired by Scandinavian style, which combines simplicity, functionality, and a closeness to nature.

SEE PRODUCTS WALL PANELS

WALL PANELSWALL PANELS

Raewood's wall panels bring warm Scandinavian style and elegant finishes to your spaces.

CEILING PANELS

CEILING PANELSCEILING PANELS

Raewood's ceiling panels add a refined and natural look to any interior, emphasizing the room's height and spaciousness.

CUSTOM SOLUTIONS

CUSTOM SOLUTIONSCUSTOM SOLUTIONS

Our products are inspired by Scandinavian style, which combines simplicity, functionality, and a closeness to nature.

Raewood is known for its reliability and dedication.

Our solid wood wall and ceiling panels are crafted to ensure durability and longevity. Relying on experience and professionalism, you can be confident that Raewood will meet all your expectations and needs, always delivering the best quality solutions on time.

Sustainability

Production Processes

Our modern equipment allows us to offer precise and high-quality services to our customers:

WOOD MATERIAL PREPROCESSING

Cutting - A format saw and multi-blade cross-cut saw allow for preprocessing raw materials of various sizes.

Planing - A 6-head four-sided planer enables planing high-quality surfaces for both square and special profiles.

Trimming - A computer-controlled cross-cut sawing line allows for fast, precise cutting of details to the correct length while optimizing material usage.

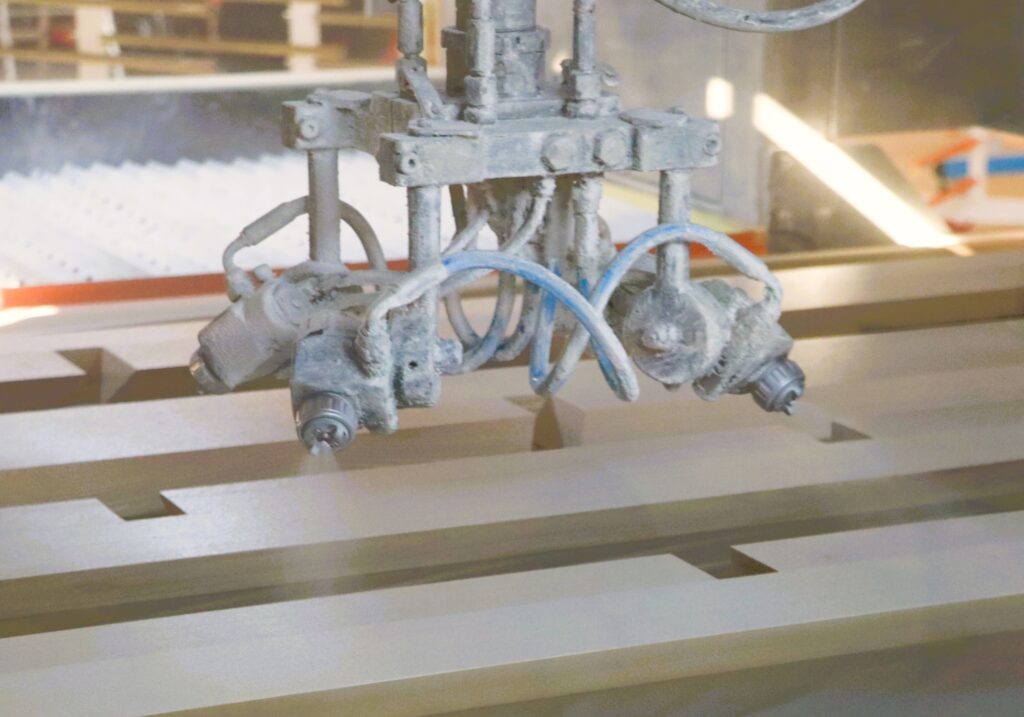

CNC MACHINING

We have a nesting-type CNC machining center that allows us to cut and process a wide range of details and sheet materials efficiently.

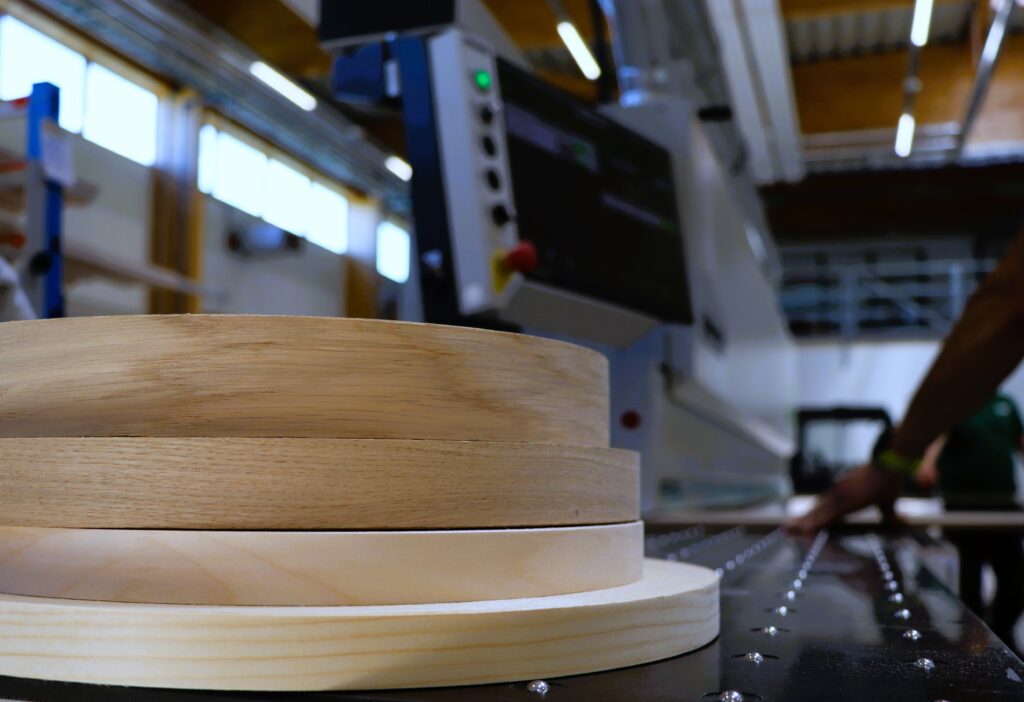

EDGE BANDING

With our edge banding line, we can apply various edge materials (PVC, ABS, veneer) and profiles (wood, Formica, plywood, etc.). We can edge band materials with EVA adhesive in thicknesses ranging from 10 to 60mm.

FINISHING

Spray Booth - Combining a 4-gun paint robot and drying chamber, we can efficiently and qualitatively finish large quantities of products. In finishing, we exclusively use modern and environmentally friendly water-based products.

Finishing Chamber - In a separate compliant finishing chamber, we can manually finish special-shaped details and smaller quantities.

Brushing Machine - The brushing machine allows for fine sanding and intermediate sanding between different finishing layers on details. Additionally, we can perform brushed surface treatments, structuring, and aging for solid wood.