Raewood - Provider of Complete Solutions for Suspended Ceilings and Finishing Panels

Raewood is a brand of Voller, which also serves as a mark of quality. The brand has defined the company's identity since 2023. It embodies quality, art, dedication, and professionalism. Based on the brand name, it is easy to identify our origin and field of activity.

Located in Rae Parish, Estonia, we primarily produce items from wood or wood-based materials. Through dialogue with our clients, ideas and solutions are born—unique and very special ones. These lead to the creation of high-quality interior and acoustic solutions made from quality materials in a socially responsible and environmentally conscious manner. We have been in the business since 1992, with thousands of happy clients.

Meie eesmärk ja väärtused

VISION

Provider of the highest quality acoustic ceiling and wall panel solutions.

MISSION

We create lasting solutions that are aesthetic, functional, and environmentally friendly.

COMPLETE SOLUTIONS

WE VALUE QUALITY

WE ARE FLEXIBLE

WE COLLABORATE

Production Processes

Our modern equipment allows us to offer precise and high-quality services to our customers:

WOOD MATERIAL PREPROCESSING

Cutting - A format saw and multi-blade cross-cut saw allow for preprocessing raw materials of various sizes.

Planing - A 6-head four-sided planer enables planing high-quality surfaces for both square and special profiles.

Trimming - A computer-controlled cross-cut sawing line allows for fast, precise cutting of details to the correct length while optimizing material usage.

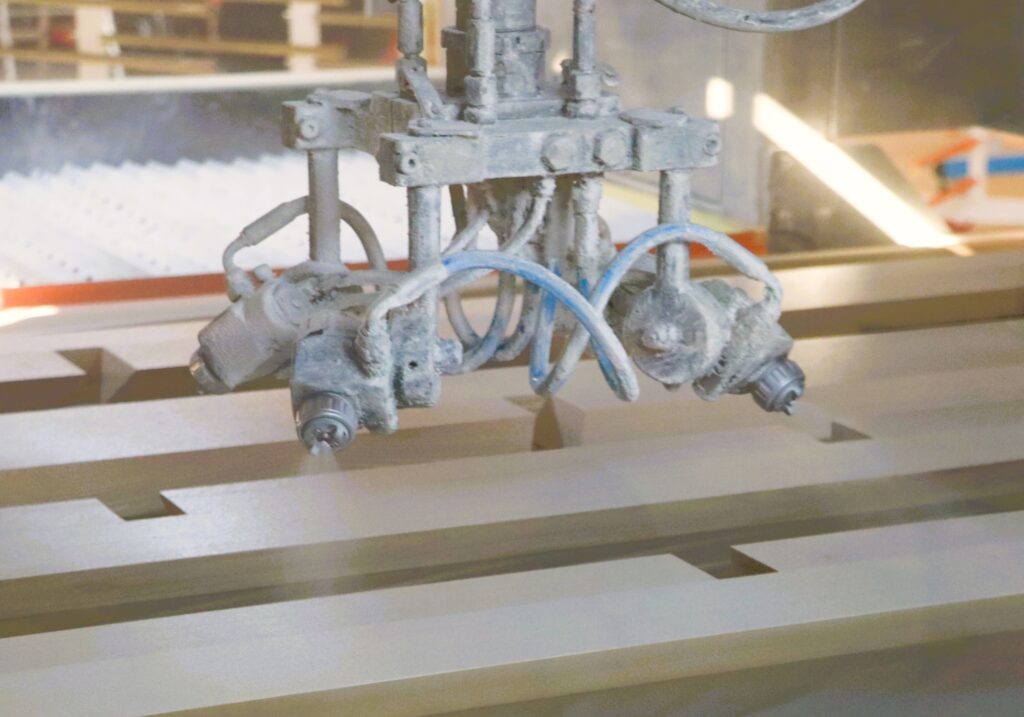

CNC MACHINING

We have a nesting-type CNC machining center that allows us to cut and process a wide range of details and sheet materials efficiently.

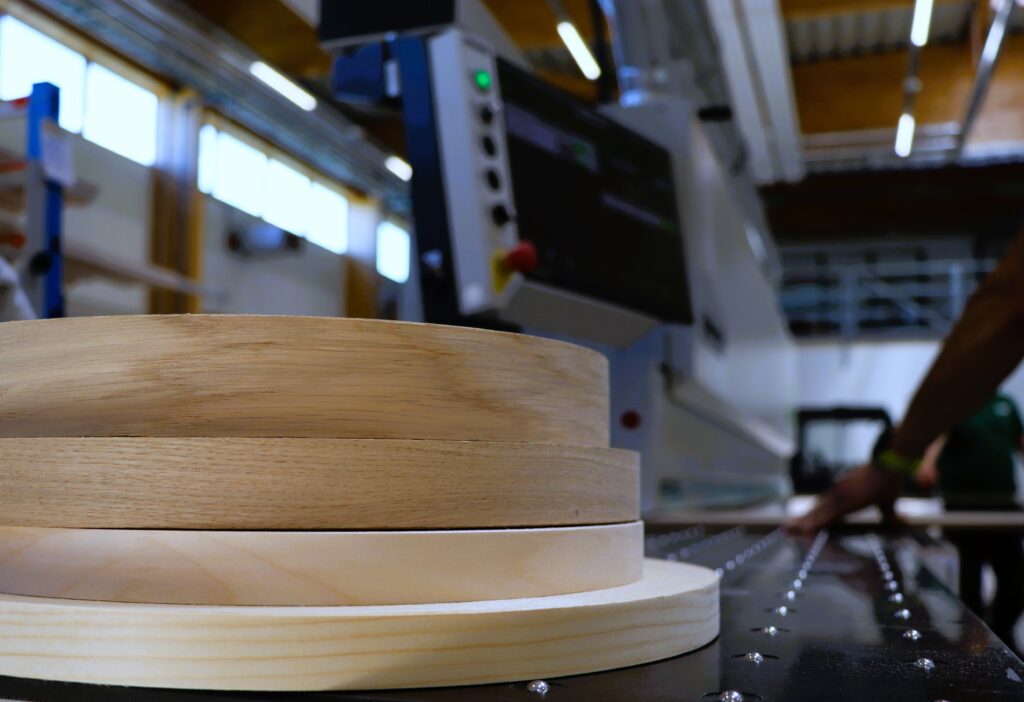

EDGE BANDING

With our edge banding line, we can apply various edge materials (PVC, ABS, veneer) and profiles (wood, Formica, plywood, etc.). We can edge band materials with EVA adhesive in thicknesses ranging from 10 to 60mm.

FINISHING

Spray Booth - Combining a 4-gun paint robot and drying chamber, we can efficiently and qualitatively finish large quantities of products. In finishing, we exclusively use modern and environmentally friendly water-based products.

Finishing Chamber - In a separate compliant finishing chamber, we can manually finish special-shaped details and smaller quantities.

Brushing Machine - The brushing machine allows for fine sanding and intermediate sanding between different finishing layers on details. Additionally, we can perform brushed surface treatments, structuring, and aging for solid wood.